One of the most useful properties of metal is how malleable it can be under the right circumstances. Either rolled into sheets, shaped into tubes, or folded into beams, metal has a variety of purposes that can easily be fulfilled by their design.

However, for more complex structures, it’s necessary to have a joint of some kind as to attach two pieces of metal together. There are two common ways to do this: either by welding or riveting. Each has its own advantages and disadvantages, so before you call the nearest mobile welding service, you might want to take a look at the rest of this article.

What is riveting?

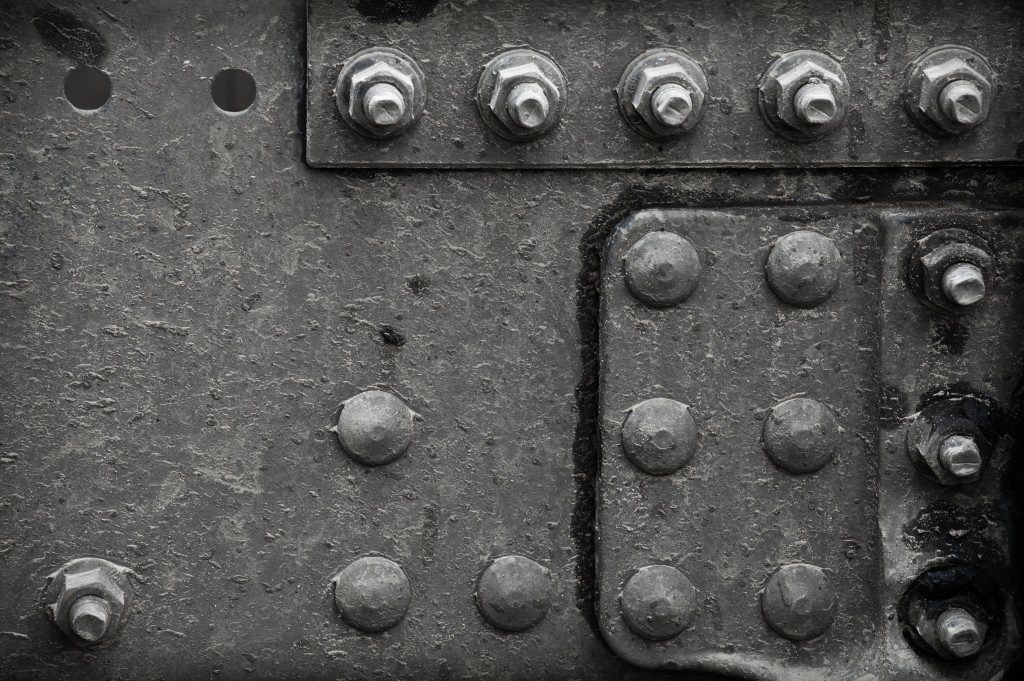

See those tiny studs on the beams and sides of bridges? Those raised pieces of metal are called rivets. Think of them as bigger and more sophisticated nails for buildings – they hold them together and protect them from falling apart to things like shearing forces (the best example would be to think of two cards on top of a deck sliding in different directions.)

Rivets have been a popular joint option before welding was invented, mainly because it relied on physics and numbers in order to hold things together. Ships, automobiles, medical equipment, and even buildings like the Eiffel Tower were constructed with the help of rivets. Since the process of applying it was simple enough, it could be used en-masse without too much requirement in terms of attachment.

The primary advantage of rivets is that they work very well with structures that experience a lot of shear force (like wings of airplanes, hulls of boats, or other similar kinds of sheet metal.) They’re easily applied via mechanical input and require little specialist tools. However, this is offset by their limits in their application, and the final output is often heavier than expected due to the rivets themselves having weight.

What is welding?

On the other hand, a weld relies on a source of heat like a welding torch in order to “melt” metal together in a joint. It’s a process that can be applied to almost any metal structure and has a variety of applications from home renovation to automobile repair.

Because of this process, the strength of a welded joint is often much greater than rivets, as the heat (or friction) securely bonds the two surfaces. Best suited for projects that require permanent joinery, welding has characterized much of the work that we do with metal today.

The primary advantage of welding is the changes it makes it the material. Welded metal is often extremely strong and weighs light, which can help reduce loads and prolong the lifespan of the welded materials. However, this is offset by the relatively high skill needed to do a good weld, as improper welding jobs cannot be repaired as easily as mistaken riveting.

Ultimately, the best way to decide whether or not you should rivet or weld a joint is to ask your local metalworker. There are different ways of joining two metal structures, and oftentimes, that will rely on a number of factors that you can’t necessarily see.